[Case Study 01]

Simplifying Warehouse Receiving

Logistics & Supply Chain

85% Faster Item Verification with a Streamlined Receiving Flow

Revamping warehouse operations to check products faster, cut errors, and boost daily efficiency.

[Project Overview]

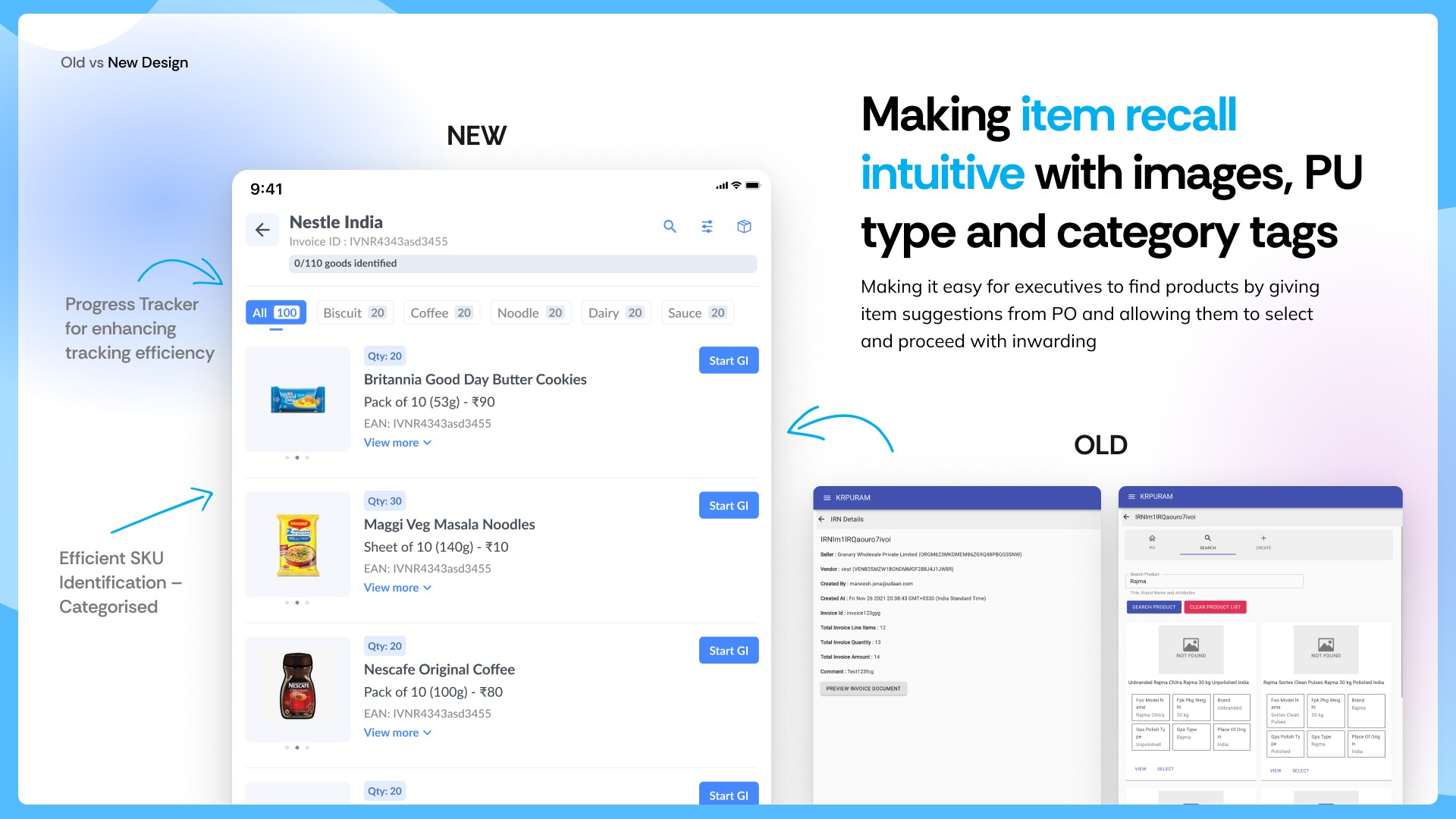

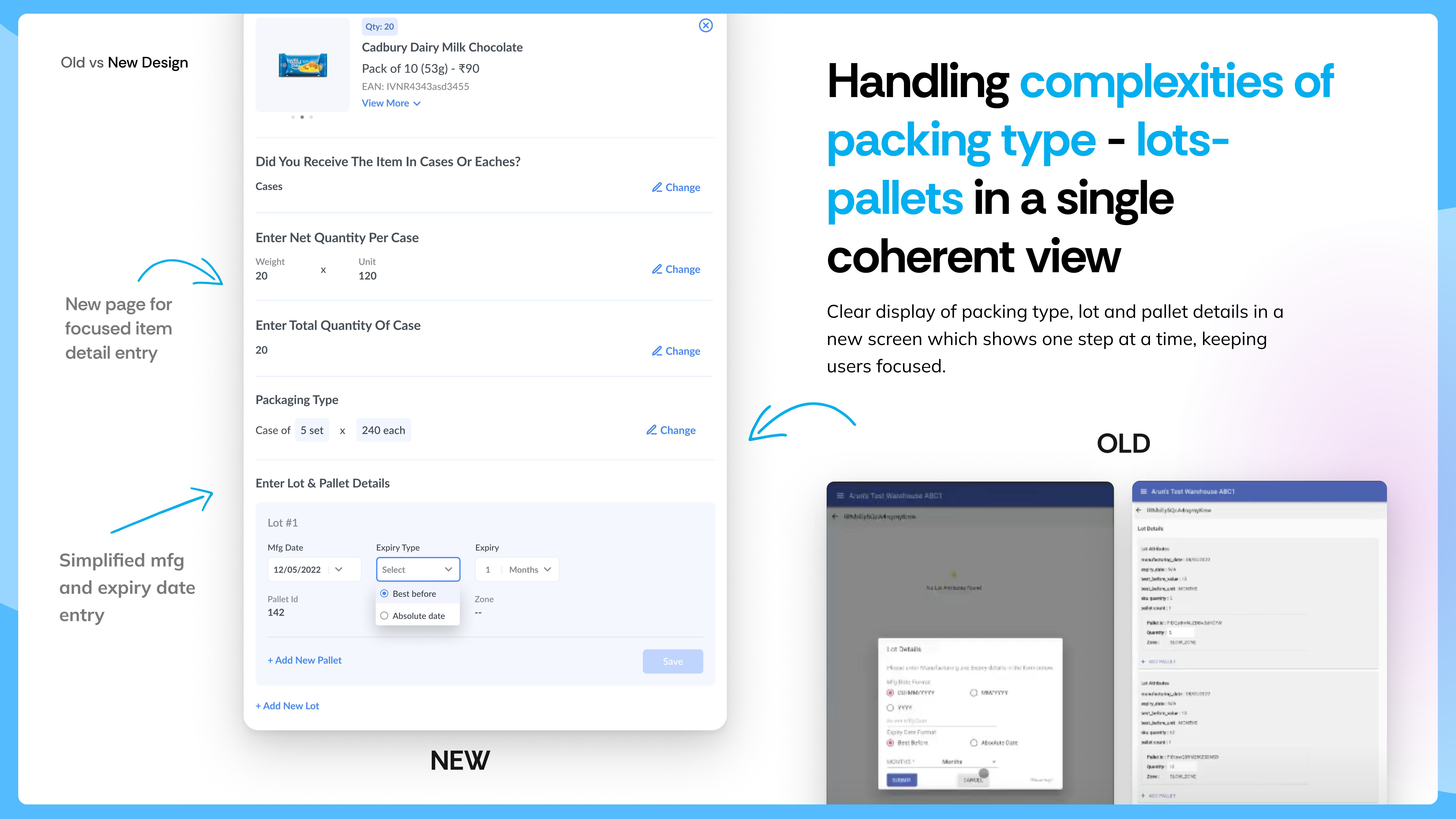

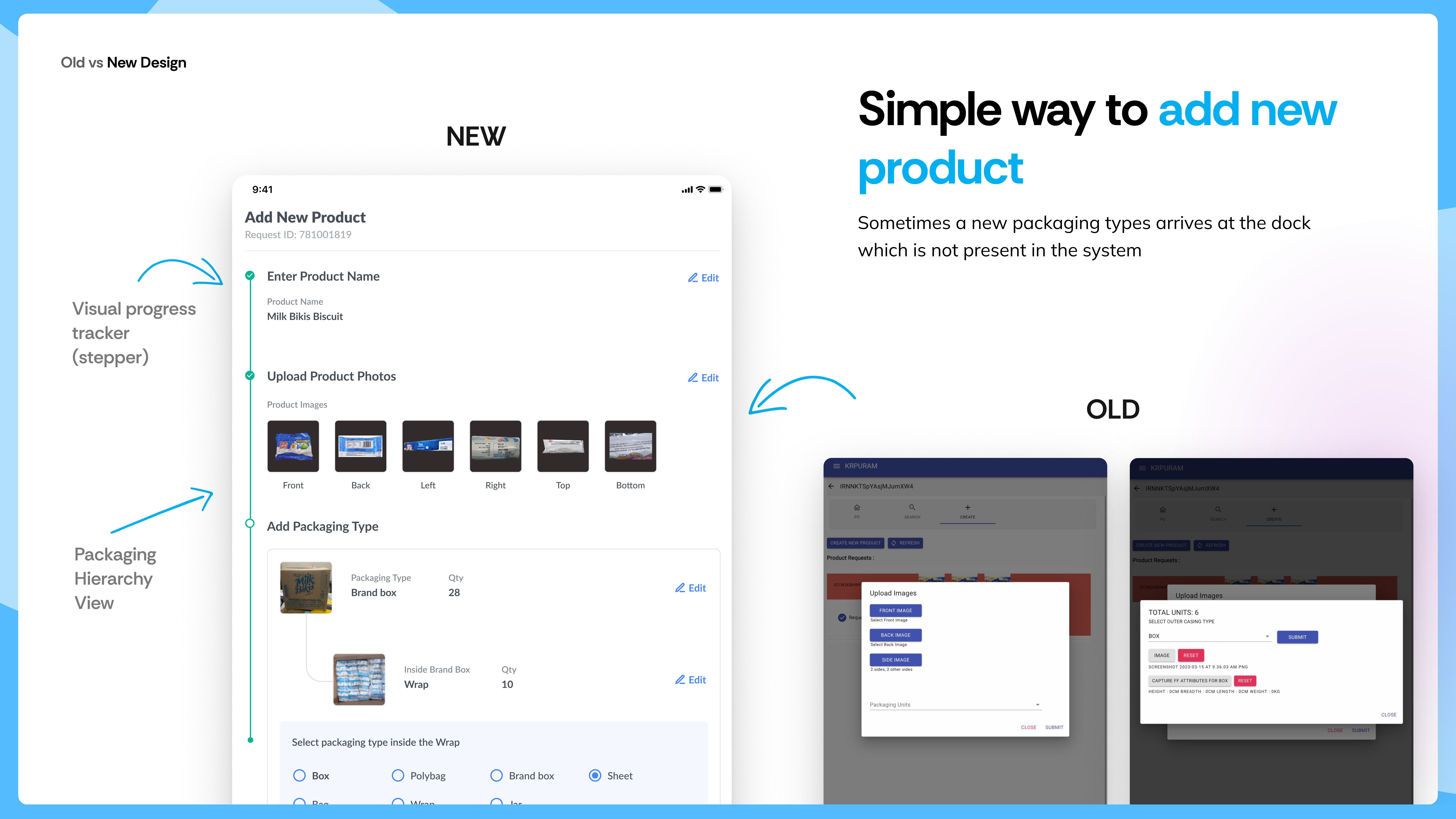

Redesigned warehouse workflows to speed up product checks, cut delays, reduce manual errors, and boost overall operational efficiency.

[Problem Statement]

The warehouse’s in-warding process combined inefficient paper-based tasks with an outdated, error-prone tablet design — resulting in wasted time, delays, high manpower requirements, and frequent mistakes. Limited device compatibility, poor usability, and long training times further slowed operations. This project aimed to streamline workflows and modernize the interface to improve speed, accuracy, and scalability.

[Industry]

Logistics & Supply Chain

[My Role]

Product Designer II

[Platforms]

Tablet and Desktop

[Timeline]

3 months

[Persona]

Arun Prakash

Warehouse picker

I just want to verify the items quickly without any mistakes.

Age: 25

Location: New York City

Tech Proficiency: Moderate

Gender: Male

[Goal]

Quickly verify received items during inwarding

Identify correct packaging units

Avoid mistakes that lead to rework

[Frustrations]

No product images leading to wrong selections

Manually identifying and marking items on paper

Difficulty in identifying different pack sizes